Manufacturing

Welcome to our website, where we provide comprehensive information about textile manufacturing. With years of experience, we deliver high-quality textile products to meet your needs. Our facility employs advanced machinery and technologies for efficient production. We carefully select the finest raw materials, including natural and synthetic fibers, ensuring their quality. Our skilled team transforms these materials into exquisite fabrics using spinning, weaving, Bleaching and dyeing techniques. We offer a wide range of textile products for apparel, home furnishings, and industrial applications. From luxurious Cotton to durable PolyCotton and high-performance textiles, we have you covered. We also provide custom manufacturing services, delivering tailored solutions to meet your specifications. Sustainability is a priority for us, as we use environmentally friendly materials and responsible manufacturing processes. Thank you for visiting our website. We are confident in our dedication to quality, innovation, and customer satisfaction. More Details as are below.

Weaving

We are proud to announce that we have semi auto looms, auto looms, Sulzer looms & Airjet looms which is ISO certified. We can construct qualities & widths according to customer requirements. In order to deliver the best quality we consume A-grade yarn to weave the fabric.. We are producing woven fabrics in 100% cotton & Poly cotton (in different blends) ie 33in to 130in widths in grey, 30in to 124in bleached/ dyed and 30in to 120in printed fabrics. Include plain, satin, twills, dobby & jacquard etc.

Dyeing

We have engaged very good Units for Continuous Bleach, Bleach, Continuous Dyeing, Jigger Dyeing, Reactive Thermosol Dyeing, Vat Dyeing, Pigment & Reactive Printing. Under the supervision of qualified & experienced personnel we are taking very good results of printing & dyeing from these units. We stay “ahead of the game” by providing our customers with the most up-to-date colors, designs, prints & fabrications. We are constantly researching & traveling the World in search of new & exciting textiles

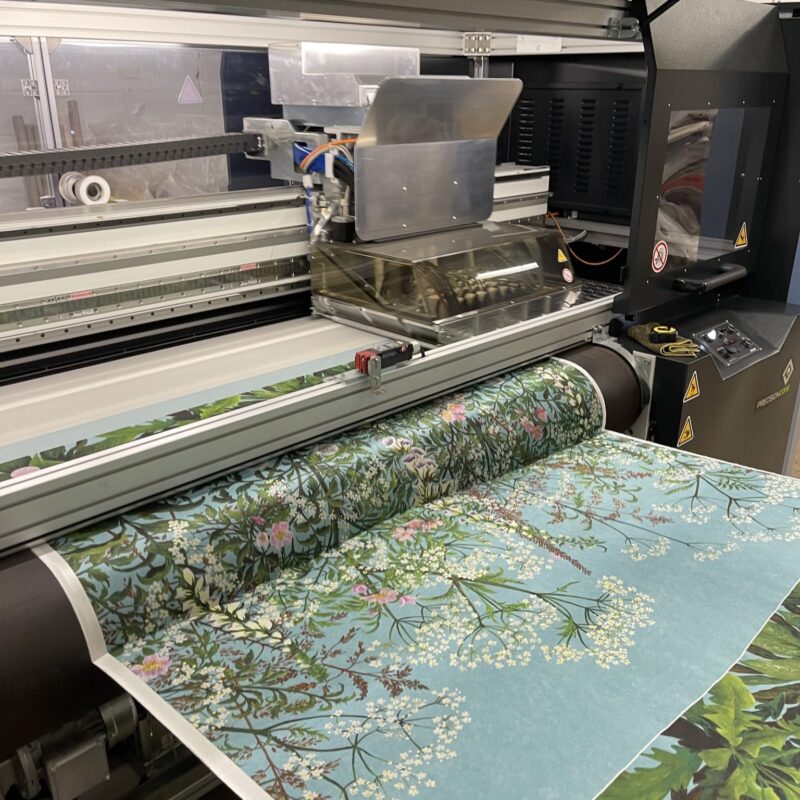

Rotary & Digital Printing

We have complete facilities for the processing of “A” grade quality. We can comply with all the tests required by the buyers in every construction. We also have arrangements for singing, continuous wash/ dying, chintz, mercerizing/ sonforizing & raising. Our production capability is 30in to 124in widths rotary machine printing with 16 colors working.as well as modern Digital Printing Machines with unlimited colors working with customized designs & Samples.

Stitching

We have very good set-up of all machines including single needle, multi needle machines, safety / Over lock machines & quilting machines. The confidence is derived from elaborated setup of more than 200 machines of various types, operated by experienced workers. Under the supervision of our Quality Control Managers everything is considered keenly from Cutting to packing process.We are producing bed sets, curtains, kitchen linen, table linen, promotional/ gift items, hotel and hospital textile (bed-sheets, pillow covers, fitted sheets, worker gowns & scrub suits)

Inspection & Packing

We normally inspect the fabrics at three times. Grey fabric checking/ mending at weaving units, checking/ screening of grey fabrics at goodown and piece to piece checking/ grading after processing. For made-ups, we have a team of skilled workers who finally inspect the goods before packing.

Laboratory

We have latest lab and skilled workers at our unit. We can comply with all the required tests.

INSPECTION BEFORE SHIPMENT

We can also arrange inspection of the goods by any international inspection company on buyers demand as well. The expenses are borne by the buyer.